60

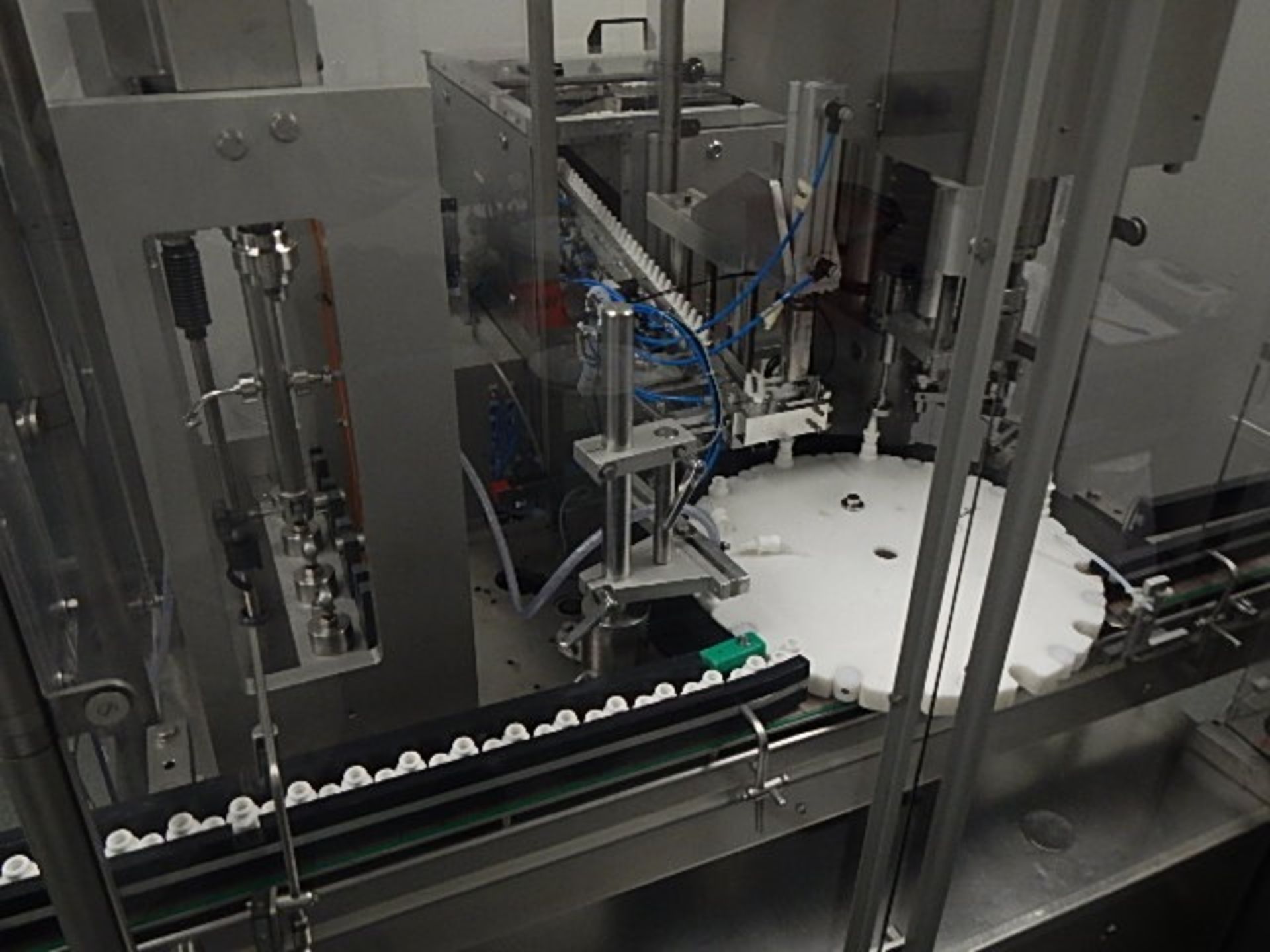

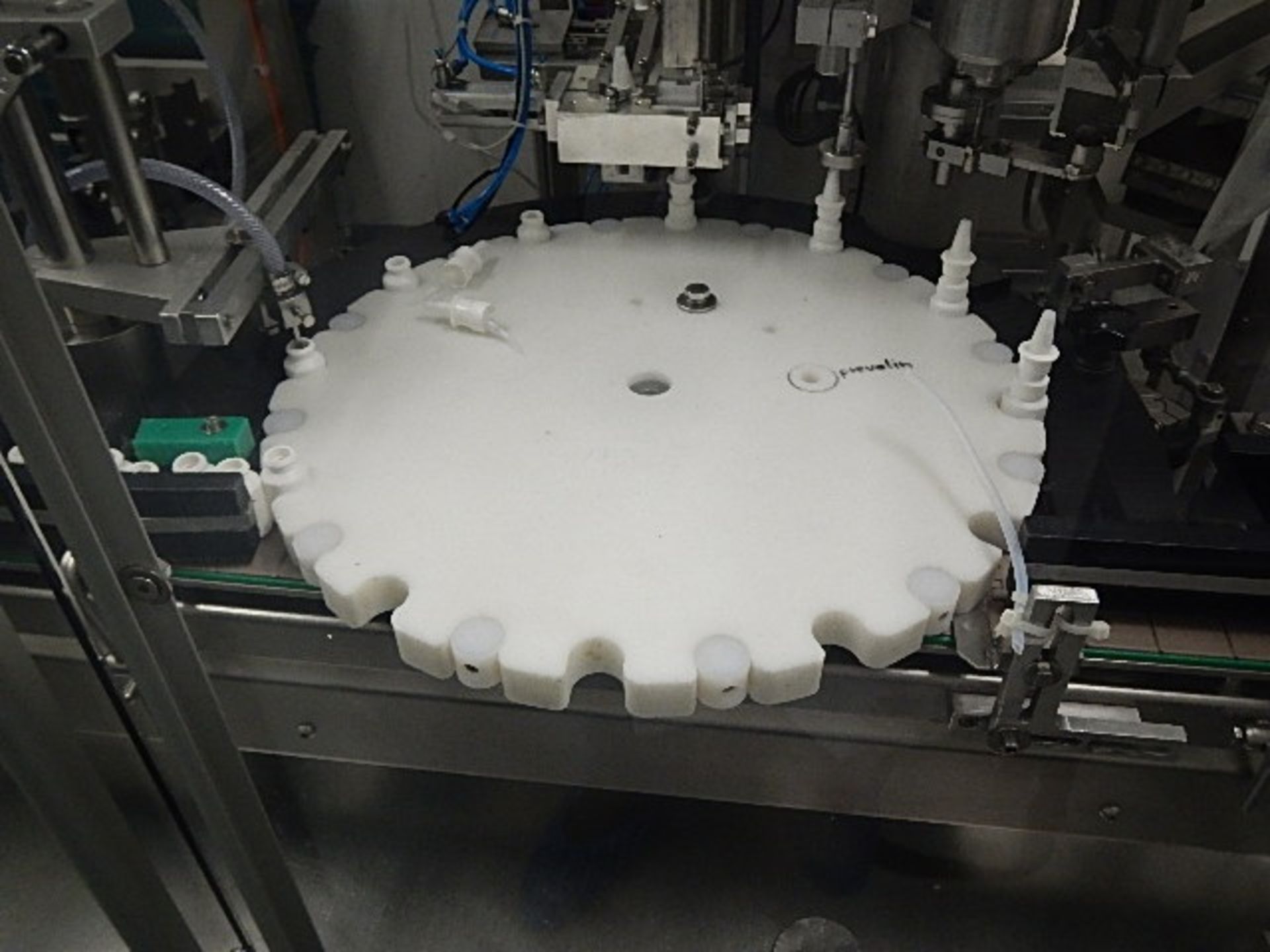

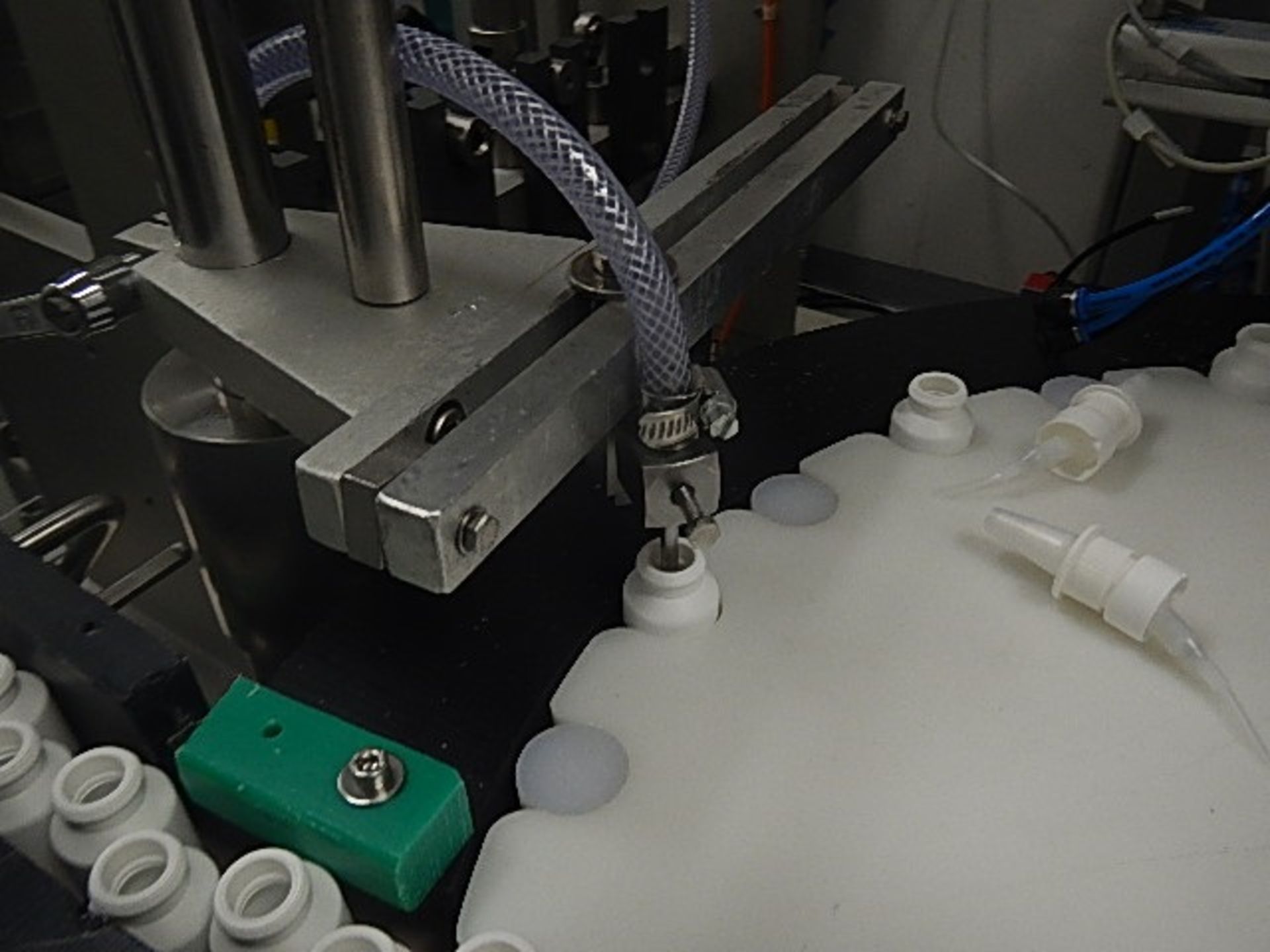

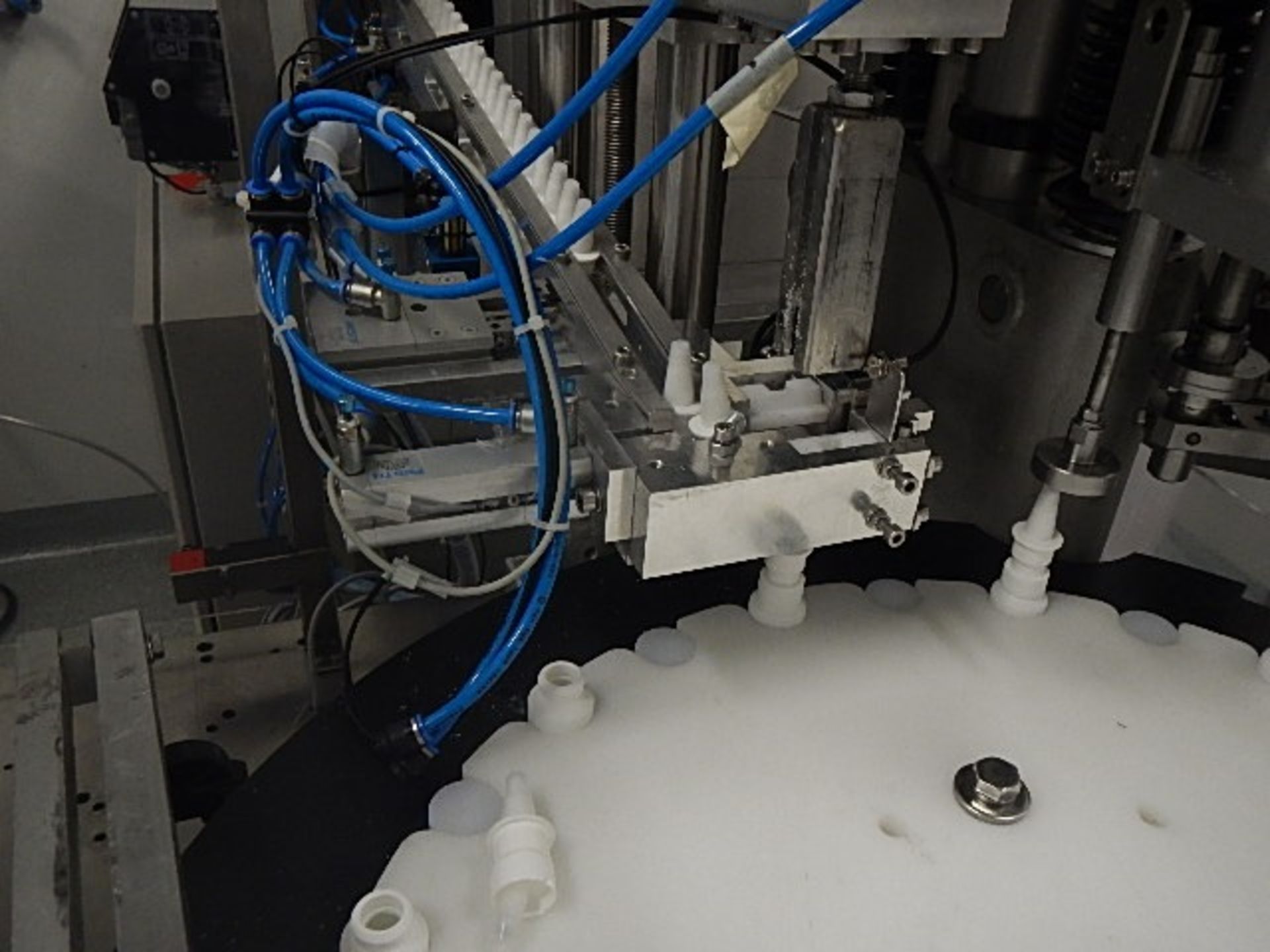

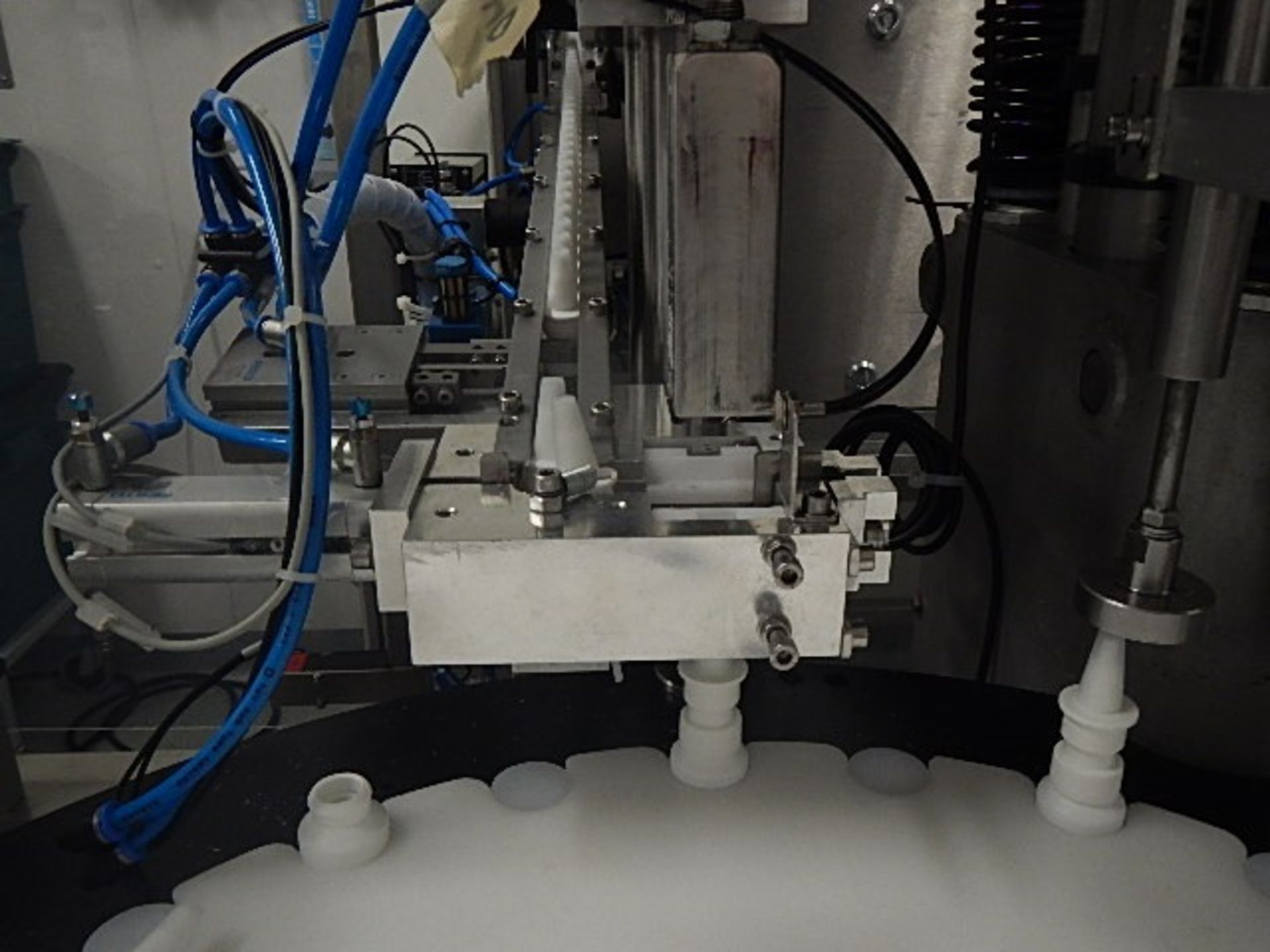

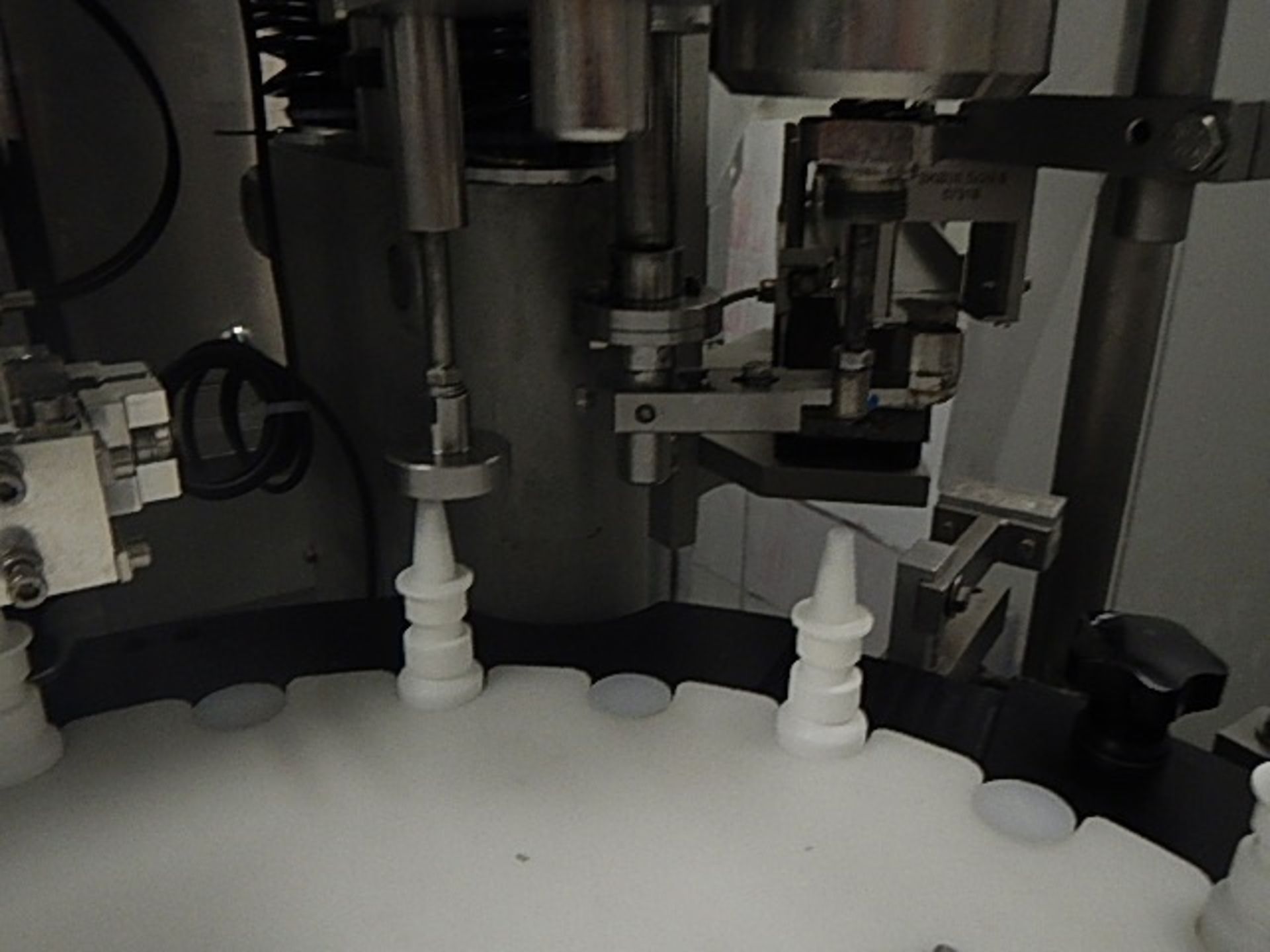

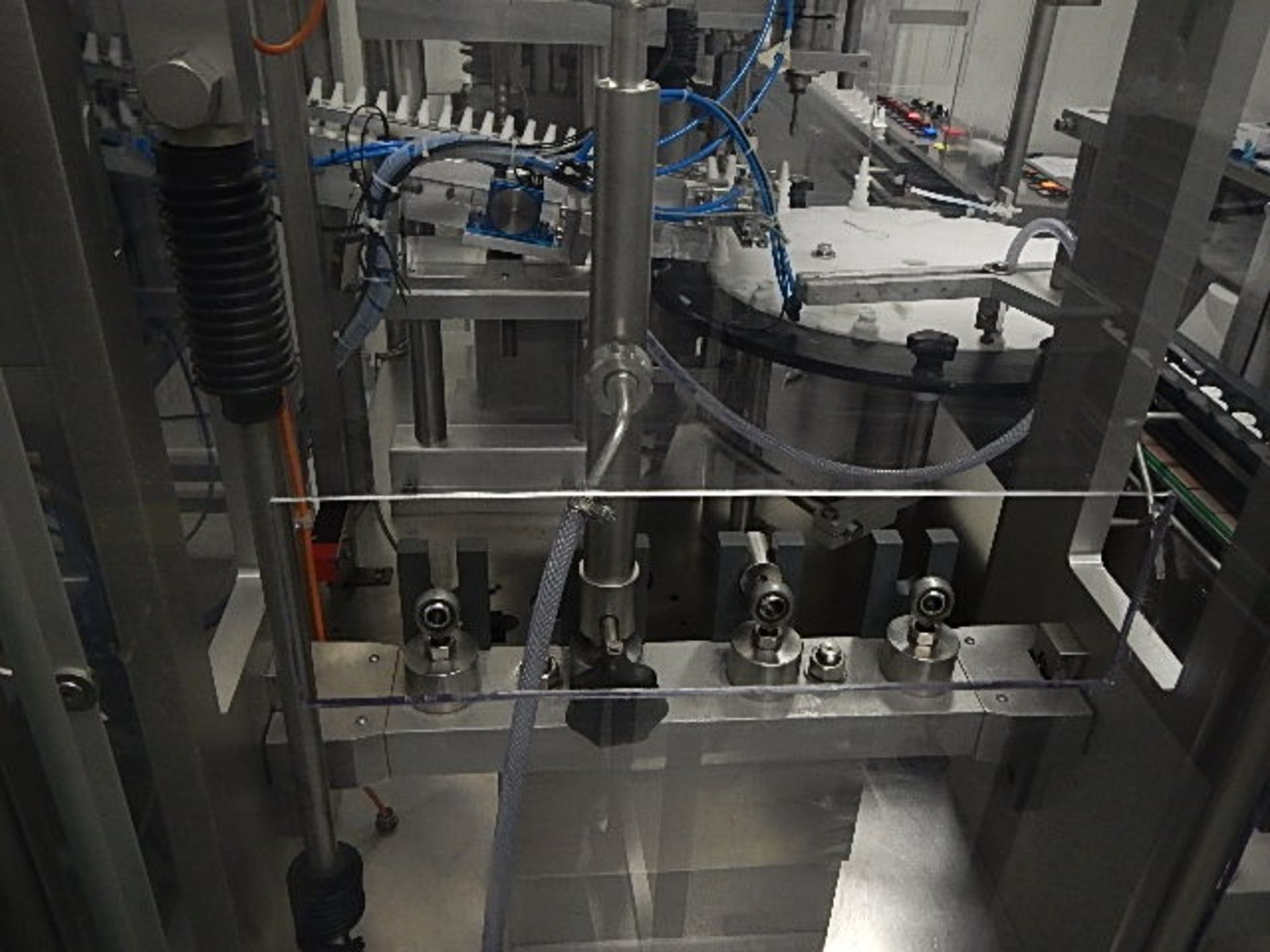

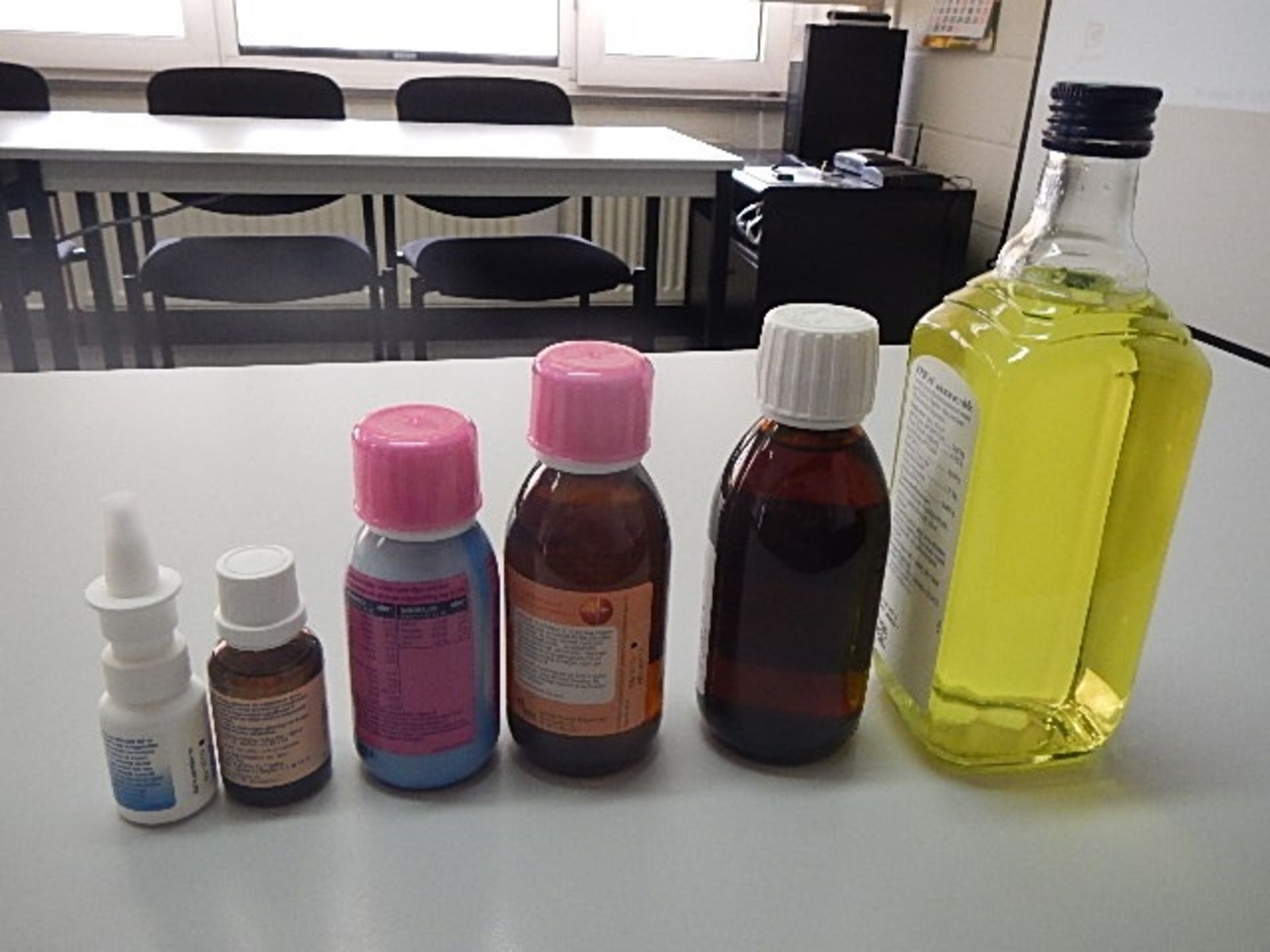

Bausch & Stroebel model KSF 1020 fully automatic i

June Pharmaceutical Equipment Auction

Endet ab

Ort der Versteigerung

Für British Pharma Auctions Versandinformtation bitte wählen Sie 07765057396.

Wichtige Informationen

Viewing can be arranged by appointment for equipment located in Flint

Appointments can be made by calling - 07765057396

Viewing days and times;

Monday - Friday 9am - 4pm

Buyers agree to pay the purchase price in full. All outstanding invoices must be paid within five (5) business days of the auction. Outstanding invoices beyond five working days will be considered abandoned. British Pharma Auctions will charge a Buyer’s premium of 15% of the final sales price + VAT. This will be added to hammer price.

Items/lots must be paid for and removed within ten (10) working days of the auction. Items/lots not paid for and removed within the required time frame will subject to a storage fees.